CEILINGS & WALL PANELS CEILINGS & WALL PANELS

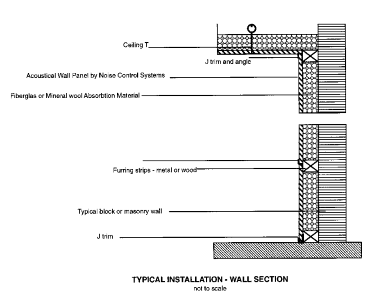

NCS Acoustical Metal Panel System is an ideal solution to provide effective reduction of disruptive or reverberant noise in commercial, industrial and institutional environments. Our metal panel system is simple to install and easily customized to fit a widerange of continuous wall and ceiling applications.

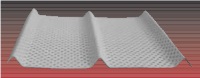

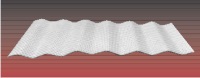

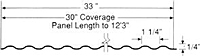

Pattern A

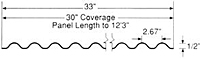

Pattern B

Pattern C-s

Pattern C-b

Pattern D

Pattern F-s

Pattern F-b

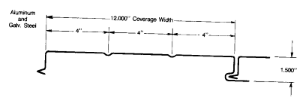

TYPICAL INSTALLATION— CORRUGATED & FLAT PAN

BAFFLES

NCS Acoustical Metal Baffles are independent sound absorbing units designed for noise control applications that do not require continuous ceiling or wall treatment. Our baffles are constructed with a metal frame covered with a perforated metal skin that houses encapsulated acoustical energy absorbing fiberglass. The perforated metal skin directs the sound waves to the acoustical energy absorbing material.

A-BAF

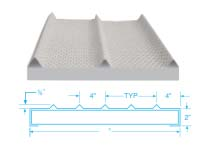

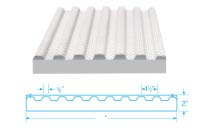

SIDELOCK PANNELS

NCS Sidelock Panels offer a "flat" field assembled acoustical wall system which incorporates hidden mounting angles and special security fasteners to provide an attractive wall surface. Our concealed fastener acoustical panel is perfect for all correctional applications as well as commercial and industrial applications which require tamper resistant acoustics.

FLAT-BAF

F-BAF

BAFFLE MOUNTING DETAILS

GENERAL ARCHITECTURAL SPECIFICATIONS

Provide metal acoustical panels as specified herein.Metal acoustical (CEILING) (WALL) (BAFFLE) panels shall be custom type as manufactured by Noise Control Systems. The metal acoustical (CEILING) (WALL) (BAFFLE) panels shall meet the requirements of Federal Specification SS-S118B; shall have a flame spread classification of 1 to 25 feet for a Class “A” rating, as tested in accordance with ASTM #-84; shall have an NRC rating of .90, as tested in accordance with ASTM C-423 for noise reduction.

B. PRODUCT

1. MATERIALS:

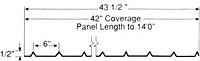

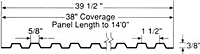

The metal acoustical(CEILING)(WALL)(BAFFLE) panels shall be corrugated using (SPECIFY N.C.S. PRODUCT)AND PERFORATED WITH A 13% OPEN AREA.The(CEILING)(WALL)(BAFFLE) panels shall be fabricated of (SMOOTH) (STUCCO-EMBOSSED)(.032 GAUGE ALUMINUM)(24 GAUGE STEEL).

2. FINISH:

The panels shall have factory applied, on a continuous process paint line, a two-coat paint system consisting of a 0.2 mil (approx.) prime coat and a 0.8 mil (approx.) finish coat of a fluoropolymer coating containing 70 percent KYNAR® 500 resins. Finish shall be cured and bake-dried to insure proper paint adhesion and uniform surface hardness.Paint color to be (STANDARD COLOR).

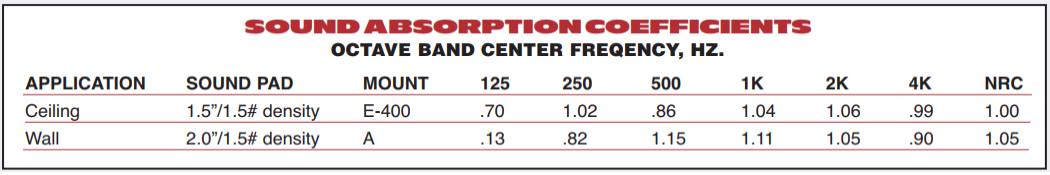

Provide FIBERGLASS insulation 2” thick and 1.5 lbs per square foot. The metal acoustical (CEILING)(WALL)(BAFFLE) panel with insulation shall have a noise reduction coefficient of 1.10 as tested in accordance with ASTM C-423 and encapsulated in (BLACK)(CLEAR)(POLYVINYLCHLORIDE [PVC] (POLYETHYLENE).

4. MOUNTING DEVICES:

As recommended by manufacturer or as required by designer.

C. EXECUTION

1. INSTALLATION:

The acoustical contractor shall furnish and install the NOISE CONTROL SYSTEMS products in strict accordance with the manufacturer’s recommendations in order to provide a satisfactory installation.All materials and workmanship furnished under this section shall be guaranteed by the contractor for a period of one year from completion date and, on written demand by the architect, any defective materials or workmanship shall be replaced or corrected.

2. WARRANTY:

NOISE CONTROL SYSTEMS warrants the metal acoustical panels for defects from the manufacturing process for one year from the date of shipment. Written notice of the defect is required.

3. MAINTENANCE:

Maintenance consists of cleaning the metal acoustica panels with a soft damp rag, warm water, and a mild soap.

ACOUSTIC CEILING AND WALL PANELS ACOUSTIC CEILING AND WALL PANELS

NCS panel systems consist of one of our corrugation patterns, flat sheets or baffle type products. These can be installed either in a suspended ceiling grid or mounted directly to a furring strip system. NCS wall panels and baffles can be installed using our typical installation procedure or, in the case when baffles are used,several types of mounting brackets are available.

GENERAL

Acoustical performance will vary depending on the specific density of the acoustical absorption material used and the construction of the panels.

ADVANTAGES

By using the panel or baffle system, this product offers the highest NRC of any acoustical product with a class A fire rating in a durable water resistant protective skin. Our products are easy to

install and are more economical than most products sold for interior and exterior applications.

ALUMINUM PANELS

Noise Control Systems recommends either perforated or unperforated aluminum panels for either interior or exterior applications

STEEL PANELS

- Noise Control Systems recommends use of perforated or unperforated steel panels for interior impact resistant or high abuse applications.

- Standard perforation is 1/8” diameter holes on 21/64” staggered centers which = 13% open area.

- Standard finishes are Fluoropolymer contains 70% Kynar 500 Resins. Custom finishes; powder coat finish.

All material is available in stucco embossed or smooth finish at no extra charge. • All aluminum items are 3000 series alloy H34

All steel items are grade A G90 Galvanized. • Perforation pattern - 1/8” diam. holes on 21/64” staggered centers which = 13% open area.